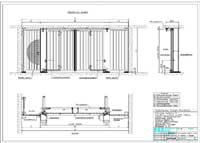

The door construction is self-supporting so that the door weight and all forces are led into the ground area by heavy pressure radial/axial bearings positioned at each side of the door.

This is the reason why there is merely no noise development when the door is in motion which could be transferred from the door to the building. The speed-and parkgate avoid the a.m. problem by the totally self supporting frame construction not transmitting any sound resonance to the building.

The supporting construction is realised by galvanised and ground painted frame profiles. The construction can be installed in front of the side-/headroom i.e. behind or in front of the light range opening so that there is a high security (the wall) of external damage by cars.

The total light range opening is free for entrance.

The a.m. tube construction carries the motor/drive box consisting of 2 spur gear drives with motor, positioned at each side of the door at the inside of the tube construction. There is as well a maintenance hatch at each side for the drives and an emergency device which can be used f.ex. in case of power failure to manually manoeuvre the door.

The maintenance hatch is secured electrically by a micro switch so that nobody can work at the inside of each drive unit with current power.

There is no drive box at the upside of the door but only a guiding track to ensure the fitting of the door in extreme tight headroom conditions.

There is no bottom track which could be an obstacle for the traffic going in and out of the parking zone nor has there to be done maintenance to clean the track or protect/repair it from damages. Finally there will be no additional costs for any ground work to lay the tracks.

The basic construction of the moving door parts is realised by a system consisting of 4 wings

(special constructions can be done as well 2 wings only to one side; 2 wings to one side and 1 wing to the other side; 1 wing to one side and 1 wings to the other side. This brings up another advantage to fold the door wings in opposite direction of a moving car which approaches. The danger of damage is again reduced to a minimum) which are connected with each other by bipartite – hinges. The hinges are realised by as galvanised axial/radial bearings with reinforced axes and joints.

The door cladding is executed as a grill to ensure that the exhaust gases of the cars can be transported from the inside to the outside of the building. In case that there is another ventilation system the cladding can be done in solid version, insulated version or in a special application as a choice of the customer. Often there is a perforated steel sheet required which can easily be applied.

In standard version the wings are filled with rectangular hollow sections, being welded to the main frame which is stiff to resist all forces of the door while manoeuvring. The dimension of filling hollow sections is 30/30/2 mm. They are galvanised and ground painted.

The hollow sections can be delivered as well in a round shape version.

The door can be painted at the fabrication in all RAL colours.